Concrete is tightly linked to the development of civilizations through their constructions. This material is composed by a binding element (usually cement), water, and different kinds of added particles. Its formula has evolved with history and its applications have been diverse, from monuments, palaces, residences, bridges, roads, and recently, furniture. The technique, technology, and experimentation have been key elements for its development.

The birth of early civilizations came with the need to build increasingly larger, more resistant, and imposing constructions with the purpose of providing the population, not only with a roof over their heads, but also with symbols of transcendence, power, and mysticism. Diverse materials were used for this task and, undoubtedly, one of the most important ones has been concrete.

In the early days, people experimented with a mix between rocks and crushed minerals combined with water, used to keep structures, made of piled rock blocks, together and to cover them. Traces of this first kind of concrete can be found in many ancient cultures: in the Egyptian’s Great Pyramid of Giza, in constructions from the Greek culture, some vestiges belonging to the Nabateans from the Syrian area, or in civilizations from Mesoamerica, among others.

The technique developed later by the Romans is undoubtedly remarkable; they created “puzzolanic concrete”, which included volcanic rocks in its formula. This compound can be comparable to today’s concrete structural features. A great example of its application was the Roman Pantheon, by Marcus Agrippa.

The fall of the Roman Empire and the arrival of the Middle Ages would bring a long stagnation period regarding development, which also happened during the Renaissance.

In mid 18th century, England resumed its use, there were experiments made with new formulas and it was used in constructions like the Tower of London. A remarkable application was made in the Eddystone Cliff Lighthouse, project that required a material, which resisted the constant wear from the waves. A hydraulic concrete was formulated with very good results. This work was finished in 1759 and its foundation still remains; since that moment, concrete and its development were back in the picture.

In 1824, a preparation was patented, which to this day is the most used; it was called “Portland Concrete”, for its resemblance with the Rock in Portland’s island. At the same time, the technology of rotating ovens was being developed. These two elements together promoted large-scale production and, in consequence, the massive sourcing of this product in the construction industry.

Some years later, reinforced concrete was introduced, the one that reinforces the structure with metal rods dipped into the mixture. This increased the resistance before bending and shear stresses. The first convincing patent of this method was available in 1892.

During the 20th century, the production and use became widespread. New structural solutions were proposed, giving way to new architectural styles, unconventional geometries, and complex surfaces, which had never been created before. The first skyscrapers were built and spaces with wider and wider spaces were possible. The development of concrete revolutionized construction.

Brutalism

In its origins, concrete was mainly used as a structural material, which in most cases was covered with some other component, in order to show a “finished” texture; with the arrival of the Modern Movement in the 20th century, the “exposed concrete” concept gained ground, highlighting the appearance and convenience of the raw material, without the need for additional cladding.

Initially inspired by the work of Le Corbusier, Brutalism was based on the precept of beauty of pure materials, their natural aging process, and low maintenance needs. This concept permeated, not only in concrete application, but also in some other materials. Brutalist constructions added elements like stairs, banisters, bars, tree gratings, and earthenware pots, along with other items that could be considered the direct predecessor of concrete furniture.

Concrete Furniture

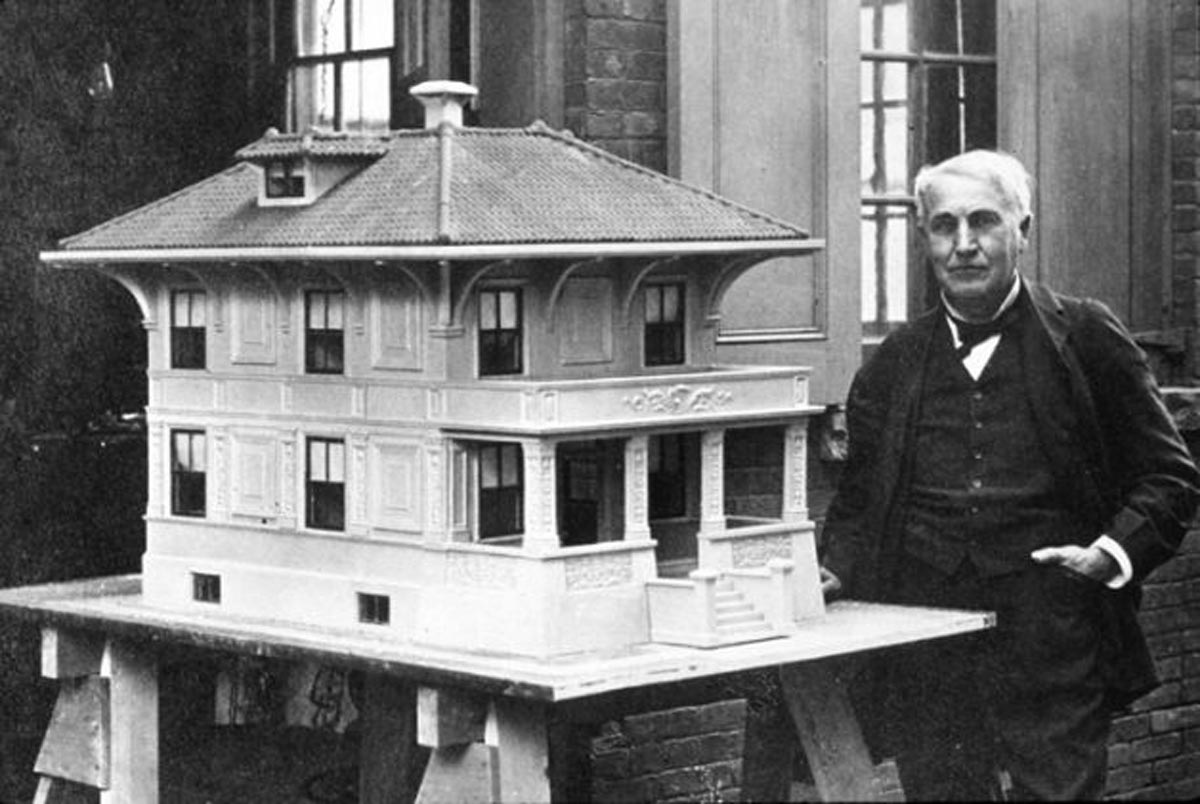

Funnily, when researching the origins of concrete furniture, a name keeps appearing within the inventor’s scope, Thomas Alva Edison, who in a quite stumbled way, participated in the emerging of this kind of equipment. In 1887, the inventor started an ambitious steel extraction project, which would fail years later. Edison then decided that, with the machinery and resources of the failed project, he would enter this new industry, the one of concrete. With the technology and breakthroughs of the time, the also creator of the phonograph, saw a great business opportunity here. He suggested creating standardized houses, which were easy to build, made mostly of this material. The suggestion was not limited to the housing aspect, he also proposed the creation of other elements: bathtubs, stairways, bases, etc. Some years later, Edison presented a piano, a phonograph console, and other pieces of furniture made of concrete.

In the end, very few of these houses were built and the pieces of furniture can only be found today in museums and galleries; this idea was not successful either. At the time, these objects were seen as a “poor” solution, it was until years later that the theoretical and aesthetic currents emerged, which would remove this connotation and allow their full acceptance.

In any case, this experiment would set the foundation so years later, through currents like the Bauhaus and Brutalism, this kind of furniture would become a reality. Weather resistance makes it perfect for outdoor use. Its heavy, cold, and rough appearance was also soon used to create contrasts in indoor spaces. Evidently, its hardness does not make it the most comfortable material; however, through ergonomics exercises and a combination of elements, this material has been, ever since, a resource for furniture manufacturing.

And so, since the mid 20th century, the use in kitchen furniture, bathtubs, bases, bars, banisters, and different pieces of urban furniture in cities across the world has become something common.

Technology

Experimentation and new ideas would come along with mass use. It would be presented in variations that go from diverse colors and textures, specific structural features, advanced hydraulic concretes, to even translucent concrete.

At the end of the 20th century, polymer concrete emerged, which consists in the combination of polymer resins, minerals, and glass fiber in different concentrations. With this variation of the material, more complex shapes could be achieved with a smaller thickness and sometimes, without the need to be assembled.

Another technology, which has contributed to this industry in recent years has been 3D printing. It has made the materialization of complex geometries easier, with a high precision degree, which would have been hard to reach a few years ago. On the other hand, this technology has been used to print houses and furniture directly, by using concrete as input material.